Greeves Sports Twin (1960) Restoration Project

HISTORY:

This Greeves has been in continuous current ownership since 1970. It was used regularly to commute between Hampshire and Cardiff where the owner studied at university. It was garaged in 1977 and stored until 2017 when a full nut and bolt bare metal strip-down restoration began which took nearly two years to complete.

Strip-down 2017

Fresh out of the barn in 2017. Looking very sad after 40 years of storage

A view showing the Triumph Bonneville handlebars. The extra width provided superb handling.

Last ridden in 1977. Note the 4T badge. The backplate was replaced when the clutch basket broke up sending shards of metal through both front and back cover plates.

A massive dent in the tank created when the stand sunk into soft tarmac on a hot sunny day and the bike fell over.

Corroded front hub and rusted wheel rim.

The strip down begins. Tank and seat removed.

Handlebars off. Note the 7" Norton headlamp and modified speedometer mount made from Bakelite!

Corroded rear hub, rusted spokes and wheel rim.

The magnitude of the restoration becomes more clear.

The silencer came from an Ariel Arrow.

Down pipes, Siamese tube and silencer removed.

Front and rear sections separated.

Front section showing the legendary I-frame and leading link forks.

Dismantled hubs showing the distinctive cooling fins. The distorted front hub caused the brake to judder.

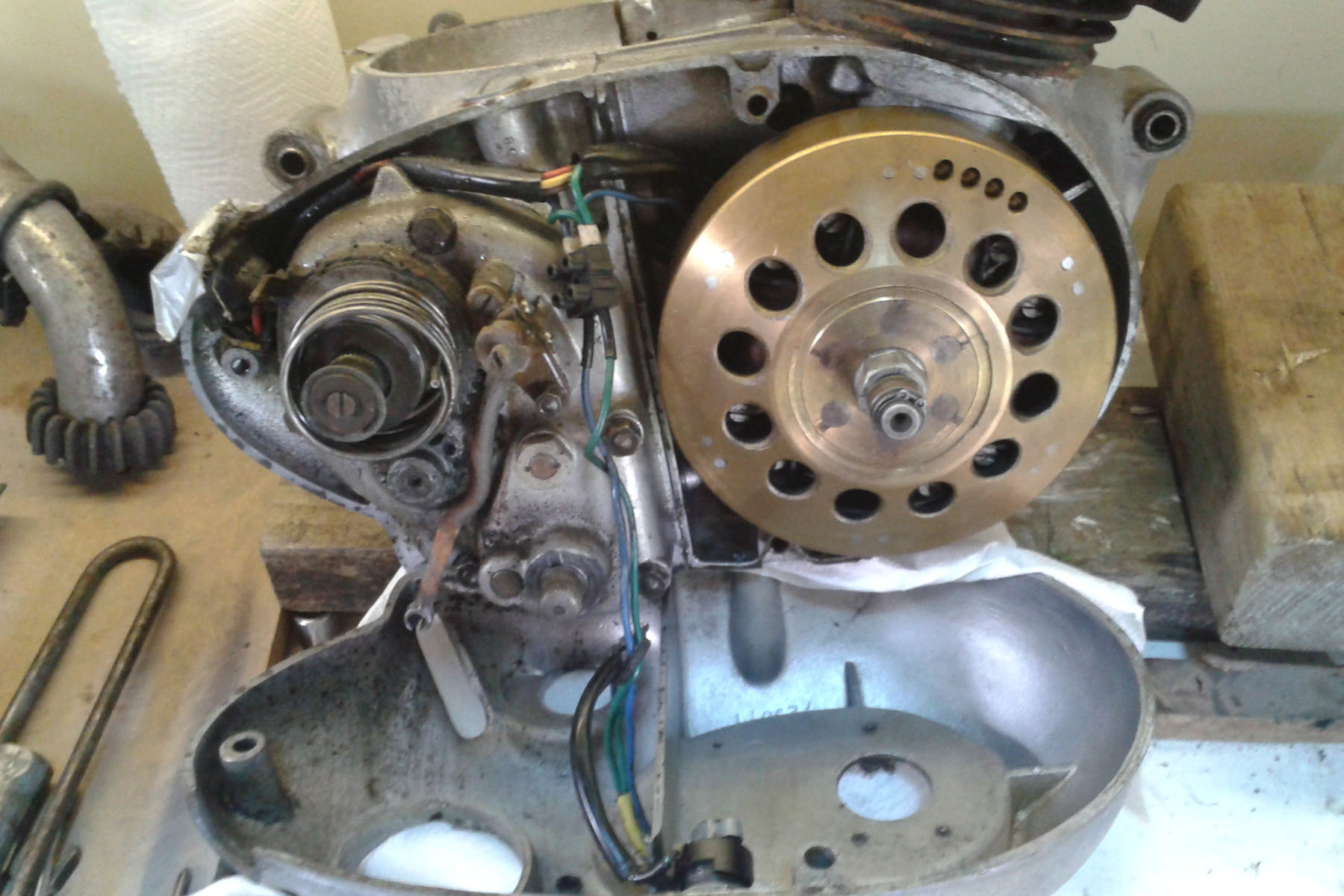

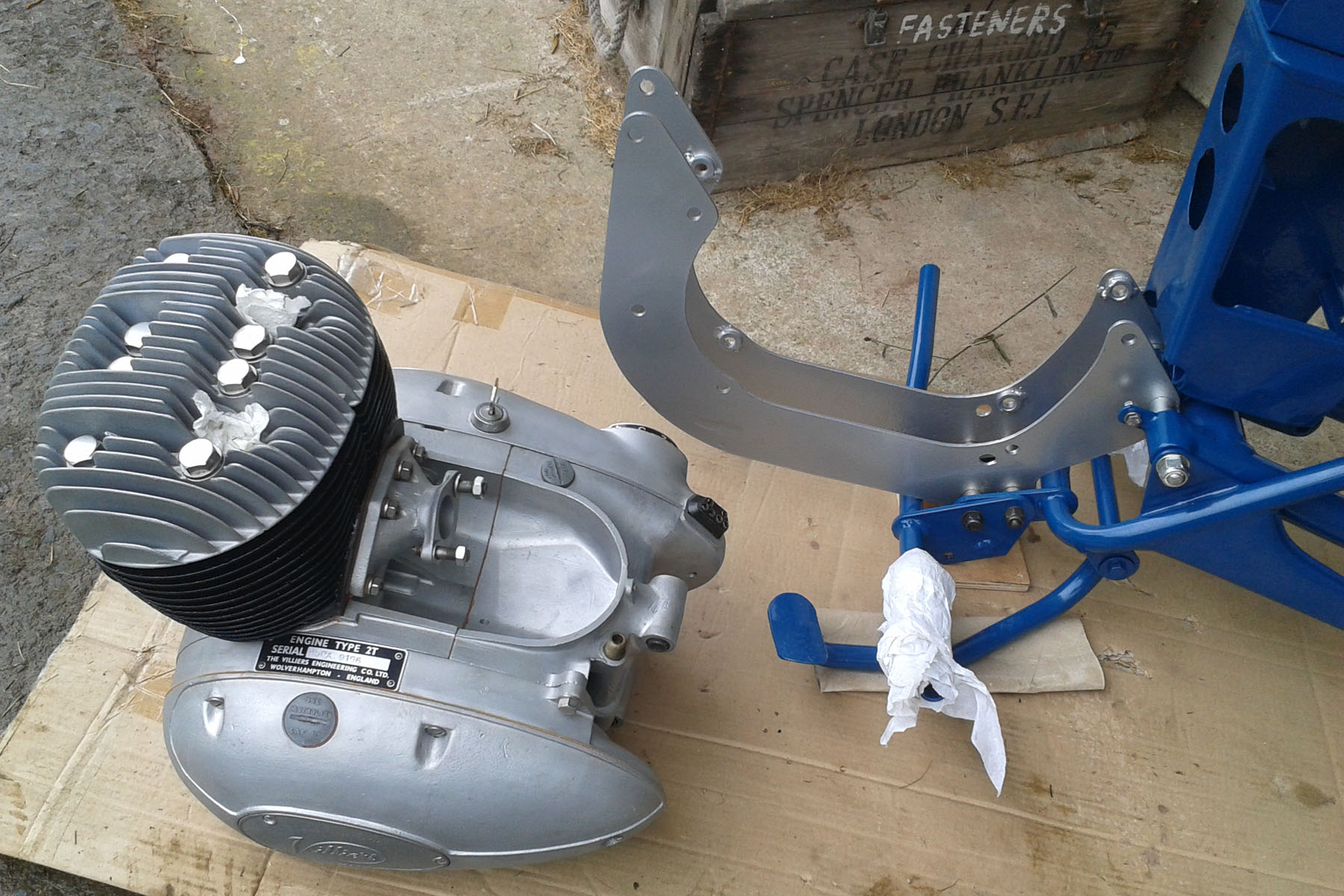

The motor unit on the bench. The 325cc 3T barrels had already replaced the original 2T barrels that kept seizing.

Clutch basket and primary chain removed. The whole unit was sent to Villiers Services for strip-down and servicing.

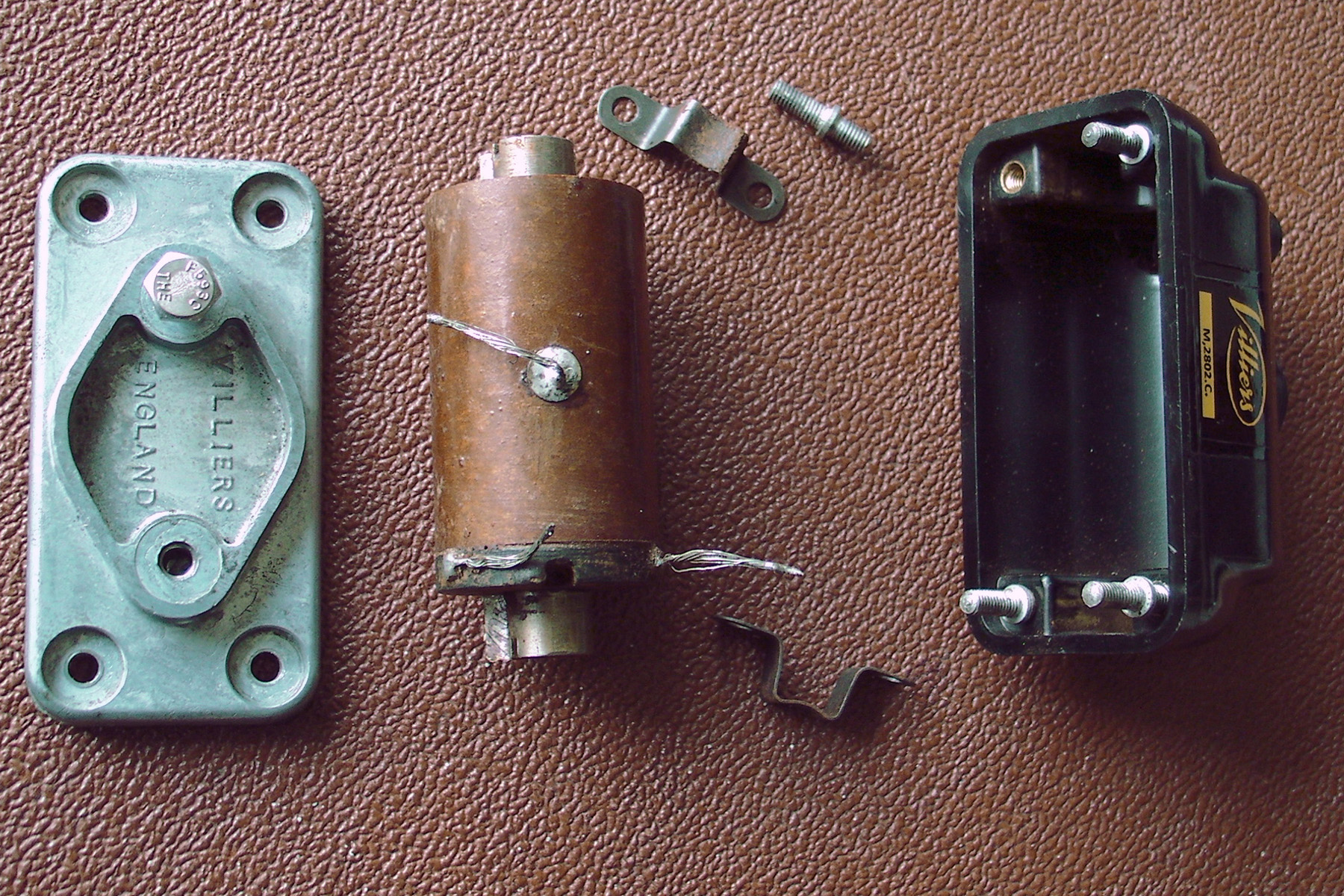

Kick-start and outer cover removed. The 'tired'. magneto required re-magnetisation.

Gearbox separated from the crankshaft to reveal the large number of spacer gaskets needed to tension the primary chain.

Rebuild 2017 - 2019

No expense was spared in this restoration. Wherever possible stainless steel components replaced the original steel ones, including replacement wheel rims and spokes.

The replacement tank purchased on e-Bay was not cheap due to its rarity.

The 3T barrels after reaming and a bare-metal acid clean benefit from an application of high-temperature paint. Villiers Services even managed to weld a broken cooling fin.

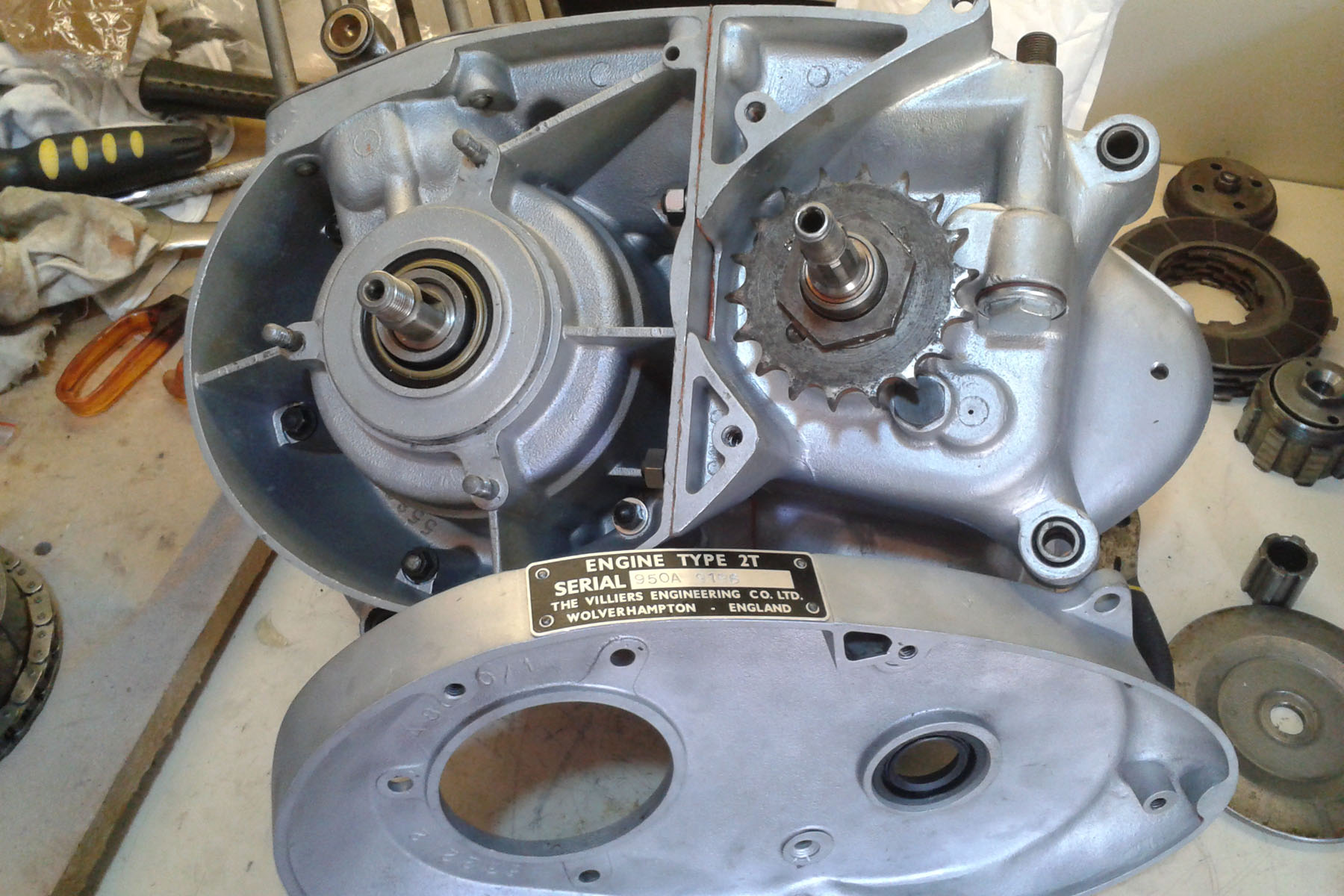

A larger 18-tooth gearbox cog was fitted to reduce the rpm for a given road speed. I would later need to fit a larger sprocket to the rear wheel as this cog reduced the rpm too much.

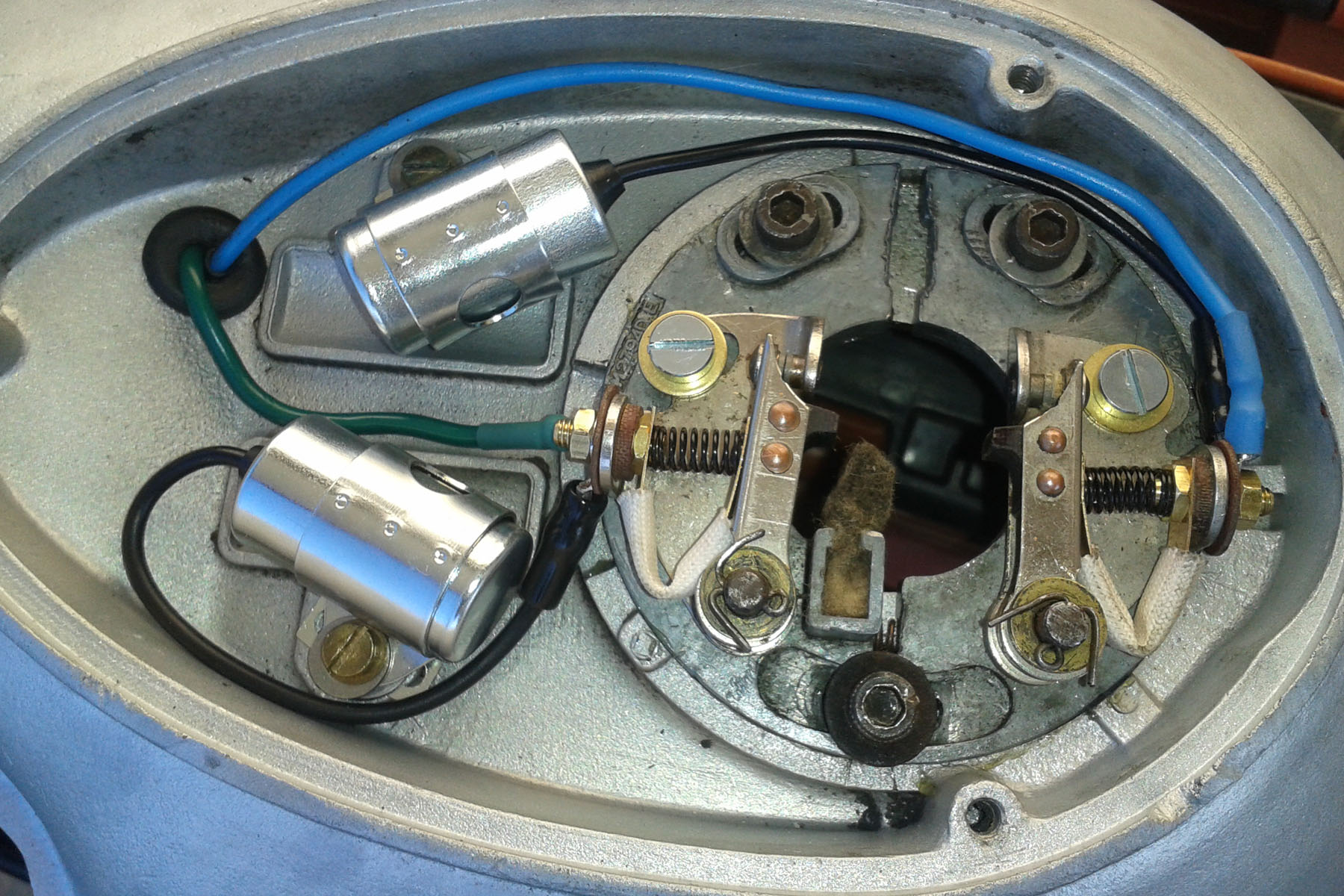

New condensers, points assemblies and wiring.

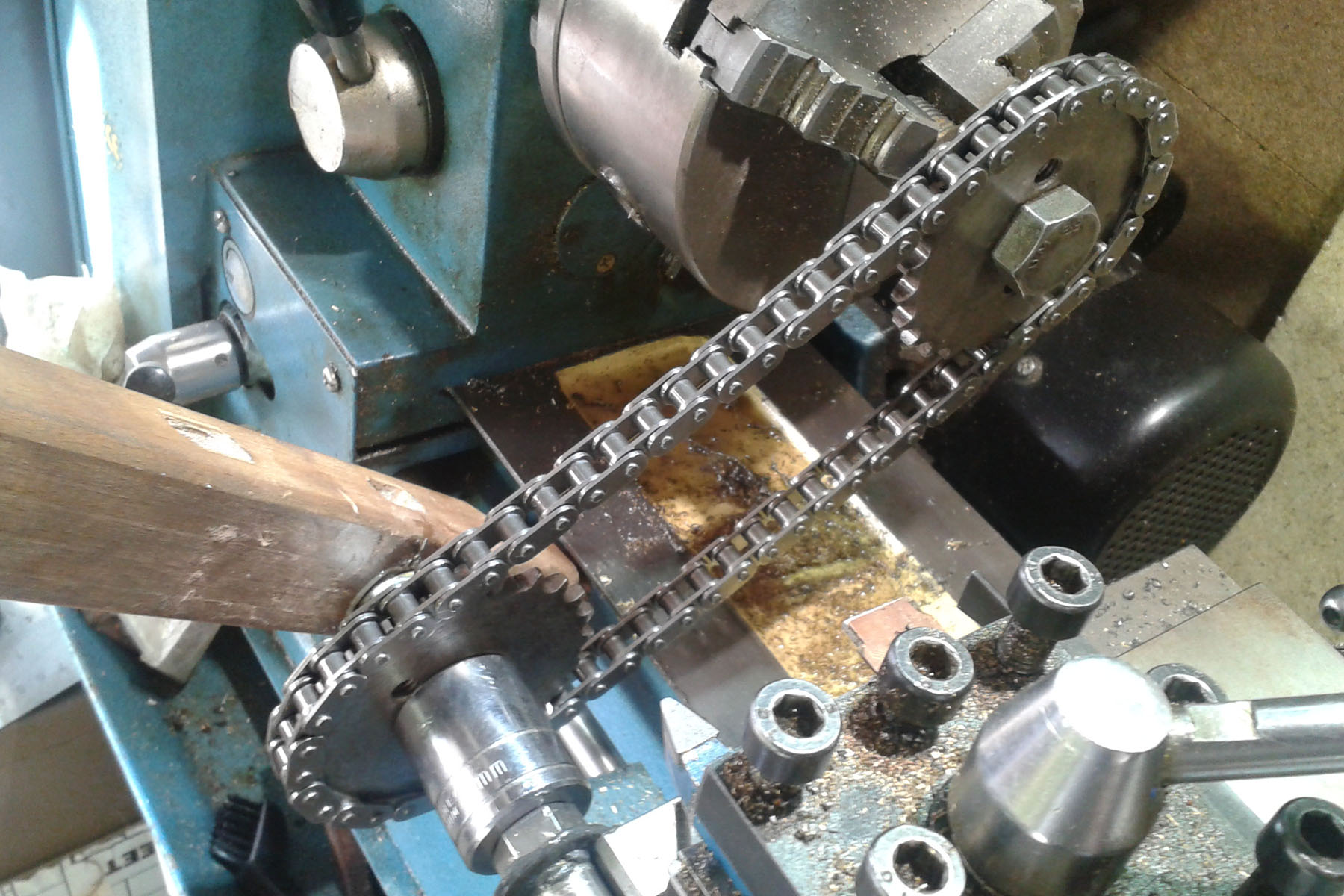

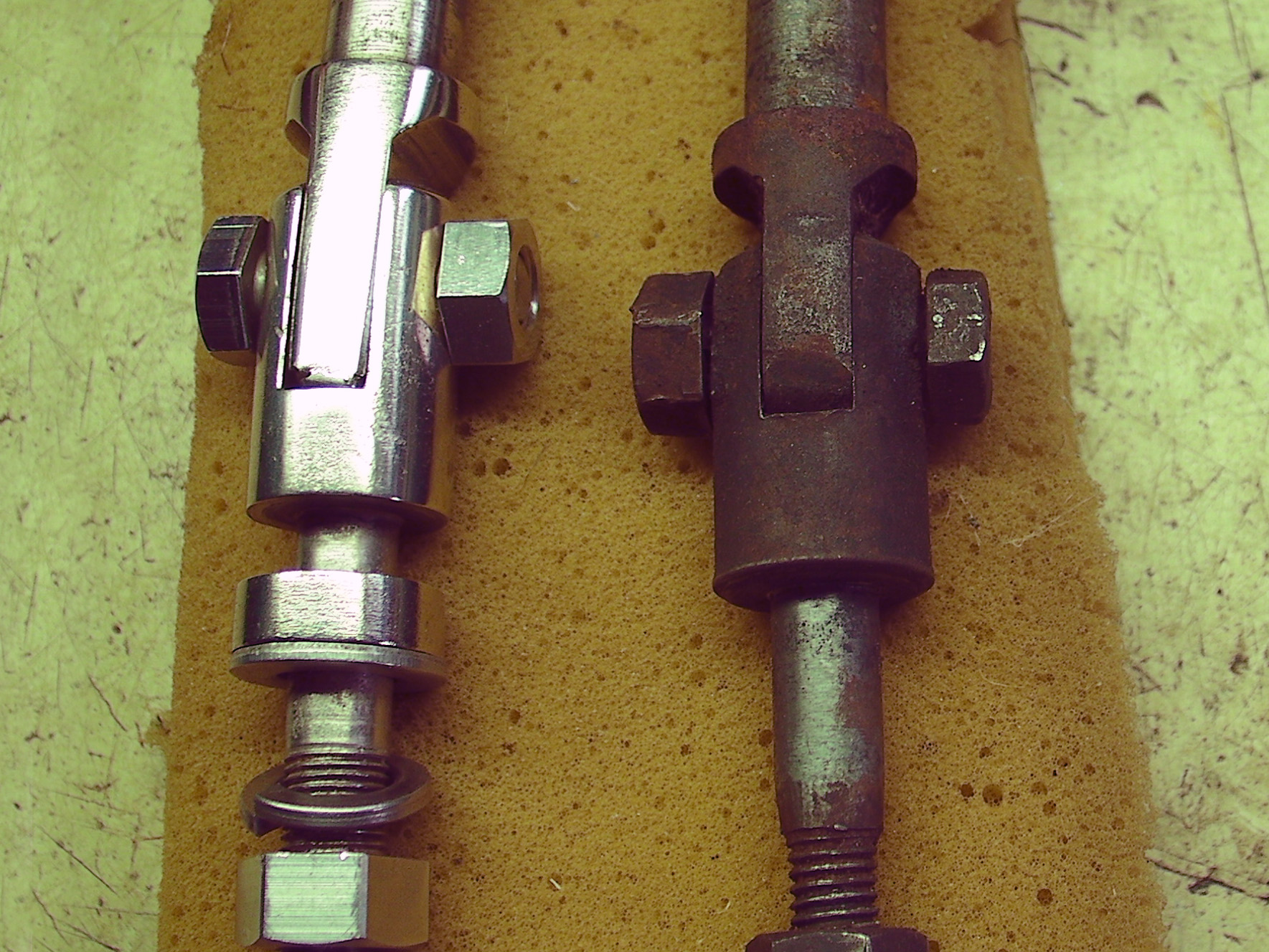

Pre-stretching the primary chain using a lathe seemed like a good idea as fitting new crankshaft-gearbox spacing gaskets later would require another complete engine strip-down.

Engine components ready for re-assembly. Over-sized pistons to match the re-bored barrels.

Back from powder-coating with original Mooreland Blue. The new wheels and spokes are top quality stainless steel and have been assembled with the reconditioned hubs, new tyres and tubes.

Main frame, battery box and engine bracket all gleaming with the fresh powder-coating.

The skimmed rear hub with new brake linings. Note the redundant speedo drive just visible in the hub.

The front hub fitted to the gleaming front wheel. Even the brake lever arm has been stripped and electro-plated with nickel-silver.

The engine unit ready for dropping into the frame. Note the gleaming stainless head bolts.

The motor unit sitting snugly in its mounts.

Engine in and front and rear frames are re-united. The aluminium I frame has been shot-blasted and lacquered for protection.

Unable to obtain new old-stock coils, we resorted to purchasing replacement coil units on line and fettling them to fit into the original Villers cases. We used a 3-D printer to make a spacer to fit between the metal body and the plastic cover so they would fit.

The hybrid coils fit neatly into the frame. The spacers were only about 6mm thick and are barely visible. Note the re-made transfers courtesy of Photoshop and an original image found on-line. Happy days!

Massive effort was put into cleaning back the rusty kick-start lever. It was then electroplated with nickel-silver; a process that took several days using home-made tools.

The rear footrests before and after nickel-silver plating. All bright steel that could not be replaced with stainless was electro-plated with nickel-silver.

New shock-absorbers, mudguard and rear light unit fitted. The number plate holder was shot-blasted and powder-coated black.

New Greeves handle-bars replace the old Triumph ones. Authenticity is restored! New levers and the powder-coated headlamp shroud are fitted.

The rear wheel is fitted. The slightly rusty cog was replaced later with a larger cog after road trials.

Starting to look like a motor-cycle again. Hooray!

A new silicon rectifier was fettled into a new cooling fin. The earthing is critical here hence the removal of the powder coating. We managed to retain the original positive earth setup.

Oops! Forgot to fit the chain guard so the rear wheel had to come out again!

Standing proud. Ready to fit and connect up the new wiring loom.

Time to wire up the components to the new wiring loom. All 6v wiring has been replaced with high-performance low-voltage, high-current wiring.

The tank and seat are on. The clutch cable has been carefully routed and mounted with custom stainless and neoprene clamps.

Forty-two years later and this wonderful Greeves is almost ready to spring into life. Note the clutch-cable clamps. Finishing details like this appear all over the machine and help to make the bike really stand out.

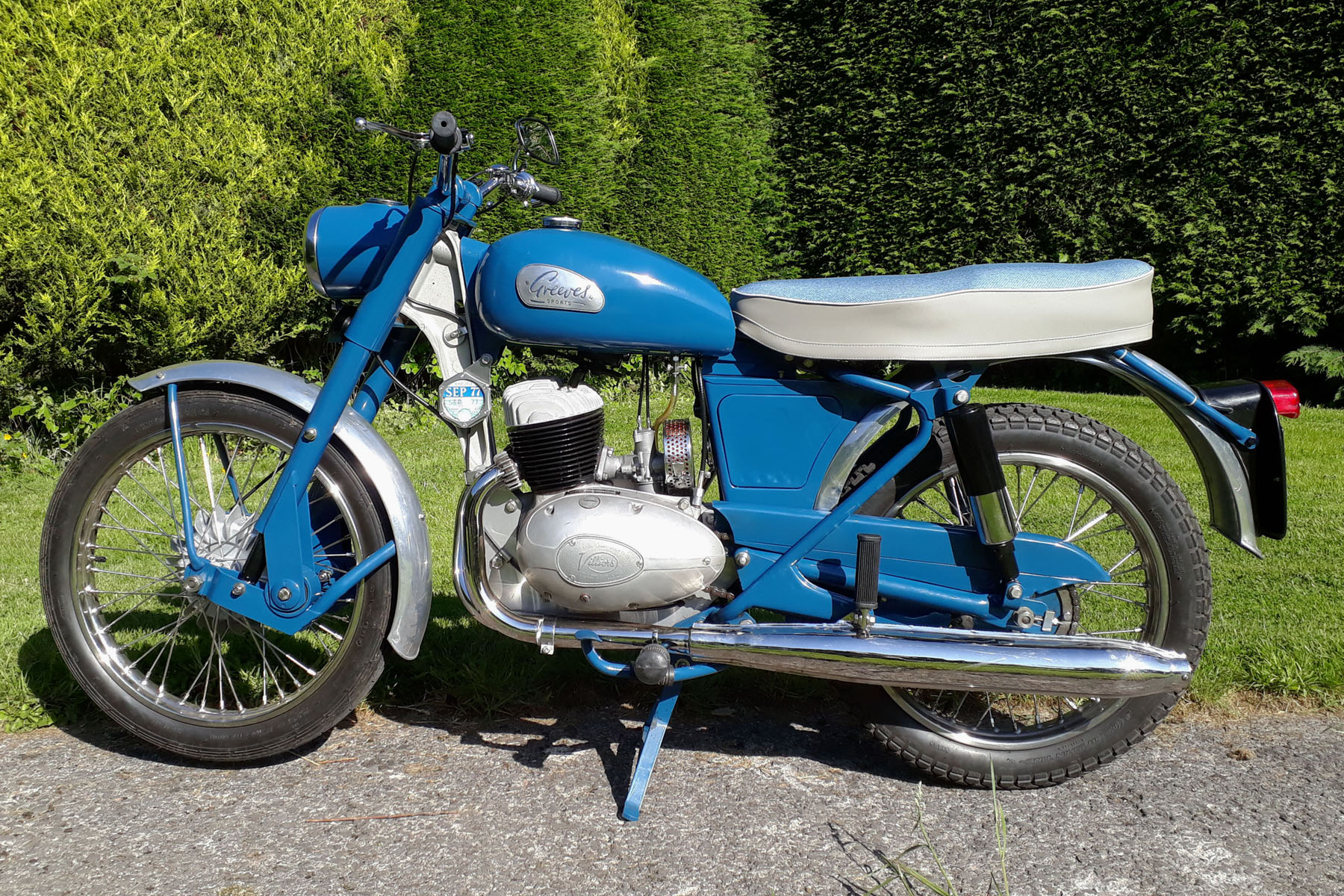

Ready to go 2019. I shall get the tank painted in original two-tone in due course.

After experimenting with the main jet on the Amal carb, she starts first kick and pulls smoothly.

I really must get that tank painted in two-tone!

Acknowledgments

To my brother, Paul, who has invested immeasurable amounts of time, expertise and patience and without whose help this would

never have happened, I offer my heart-felt thanks.

Thanks also go to Steve and Lewis at Villiers Services for their expertise, experience, and their amazing ability to resource

items that went out of production many decades ago, and for their continued support.